What’s the biggest expense at your warehouse or distribution center? If your operation is like most, the answer’s probably order picking: Research suggests that order picking makes up between 50 and 75% of warehouse operating costs. If you want to build a more efficient operation, then, look for ways to improve order picking productivity.

That requires a careful plan and the right layout. But both of these factors depend on warehouse shelving systems that make efficient travel patterns possible. In short, the industrial storage solutions you choose have a direct impact on order-picking productivity.

Your warehouse shelving must fit into the facility’s space itself, creating aisles and traffic lanes that allow order pickers to access contents without congestion. Of course, warehouse storage systems must also be designed specifically for the materials and products you handle.

Before you choose the industrial storage products that improve throughput for your operation, take the time to understand all the options. That research begins with this article. Here are some of the leading categories of industrial storage for warehouses, distribution centers, manufacturing operations, storerooms, and other commercial storage facilities.

Industrial Storage Solutions for High-Throughput Operations

1. Pallet Racking

If you typically handle materials at the unit load level — and those materials are always stored on pallets — pallet racking will form the core of your warehouse operation. Pallet racking comes in a variety of configurations and designs, but according to the Rack Manufacturers Institute (RMI), there are two general categories of pallet racking: roll form and structural construction.

While both types are made of steel, roll form racking is generally lighter, thinner, and easier to install than its structural counterpart. It’s also less durable and more vulnerable to damage from lift truck strikes. That makes roll form racking a common choice in lighter-traffic warehouses and commercial operations. Higher-throughput operations often choose structural racking, since it can withstand more abuse.

Within each category, common configurations for pallet racking include:

- Selective Pallet Racking – This low-density configuration typically stores pallets a single layer deep, which allows lift trucks to access every pallet without a lot of shifting. The trade-off for this access is that selective pallet racking layout requires wide aisles, so there’s less room in your facility for storage itself.

- Very Narrow Aisle (VNA) Racking – VNA racking achieves higher storage density at the cost of aisle width. You need special VNA forklifts to access pallets in such a system, and only one vehicle can access an aisle at a time.

- Pushback Racking – These high-density storage systems are deeper than selective racks, allowing lift trucks to store pallets up to six units deep. This design supports a Last In First Out (LIFO) access strategy, which is why pushback racking systems are sometimes called LIFO racks.

- Drive In Racking – These storage systems achieve even higher density than pushback racks by storing pallets many units deep. To access these pallets, lift trucks must drive into the racking system, then back straight out.

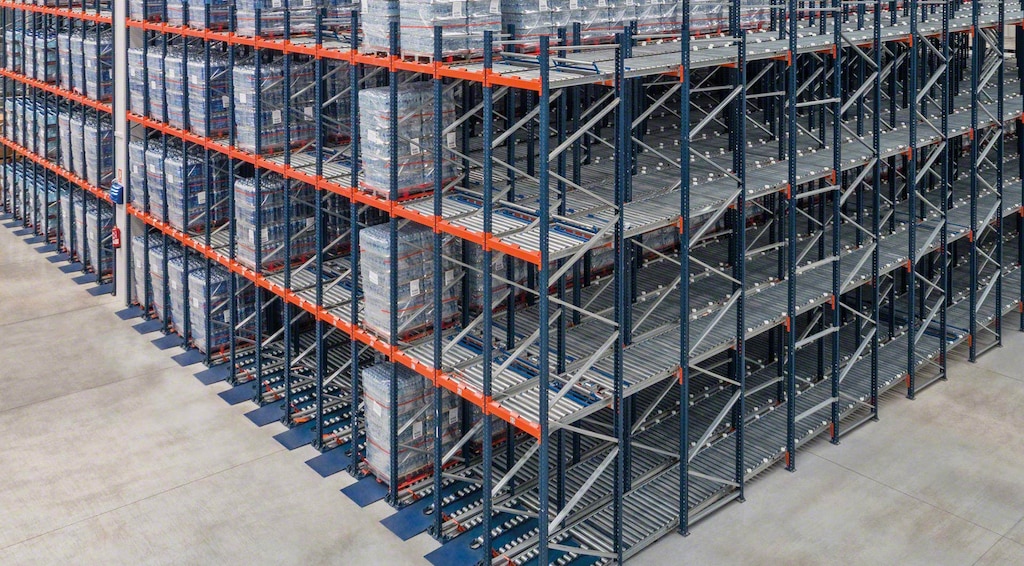

- Pallet Flow Racking – This design takes the concept behind flow-through racking and expands it to support pallet loads. Lift trucks load pallets into the racking system from the rear. A gentle slope allows gravity to draw the pallet toward the front of the system, where lift trucks can access them for retrieval. This design supports high-density storage in a First In First Out (FIFO) access system.

To choose the right pallet racking system, you must consider the standard weight of your unit loads; available material handling equipment; and all your local building and fire codes. But what if you store items or materials that don’t fit onto pallets? That’s when you need one of the other industrial storage solutions on our list.

2. Open Industrial Shelving

For most non-palletized storage situations, open steel shelving is the go-to solution. Welded steel racks with fixed shelf heights provide the best combination of stability and impact resistance, while a powder-coat finish will add to the unit’s long-term durability.

Look for a steel shelving provider that can provide custom shelving systems to match your materials or products. Consider your required storage capacity, shelving layouts that preserve floorspace in your facility, and overall shelf height.

3. Flow Through Racks

To really speed up order picking and access to small parts or components, look for a storage solution that keeps product close at hand. Flow Through Racks and Gravity Flow Racks feature included shelving that draws contents to the front of the rack, where staff can access it easily. This self-replenishment improves productivity while reducing ergonomic risks like reaching and bending.